The repairs have now been finished and in the last 5 weeks we have been non stop fitting out-including loading 10 tons of ballast.

The services are in, the welds were ground and more red oxide put on before the undercoats and now all the paint is done .(we even managed to black the bottom plate).

The lining is almost finished and the floor is laid and sanded and will be waxed by Friday when she wll finally go on the water.the services are finished to end points and the wind and solar will be fitted on the watr which means we will pole it or be towed until the week after launch!

My friend Noel ame down 3 weeks ago and has helped Andrew non stop- 8am-11pm most days.

i have been there quite a bit but have found the whole experience so stressful that most of the time I am unhappy .We are owed almost £17,000 and do not forsee it being paid back even although we have a court clam pending (no money in the business). Parenting and going back and forward is also a drag -it takes 1.5 hours to drive it.

however now that more is done I can see it taking shape and have said that providing certain things are up and running I will move in.

Andrew and Noel have been living in a caravan we got cheap on the campsite at foxhangers. i got a gas bottle converted to a wood burner installed and the caravan heats up to 90 degress in no time!

We even managed at the last minute to get the hatch corected to our origional specs which means the spiral stairs will fir.The calorifier webasto radiator outfit is fitted as is 2 pumps -a grand total of 34 L pressure rather than the usual 17L so the bath will run fast enough and the shower will be powerful enough for all three of our long thick manes.

We went for 240 lighting and chose megaman low energy surface mounted and thin recesssed (23mm) lights which take 9 and 11 watt bulbs.

My daughter who has also suffered the last 4 months -mainly from us being stressed and working flat out ,is saying she does not want to move on so we are tempting her with a 2 wek holiday cruise once we move in. Andrew will move in on friday when it goes on the water and i am aiming for 2 months after that with my kitchen and bathrrom working and no tools all over the place proviso.. wll update after she goes on the water Bradford on Avon

Tuesday, November 06, 2007

Sunday, October 07, 2007

3 months on /heartbreak

its been so ong since i wrote.

disaster has struck.

there were problms with the structural steel work and there has had to be 'repair and restoration' workathough on the whole everything is fine now-we are wed the money by the blder -12 thousand pounds, we do not want to go to court but will if we have to

the boat is now just about ready for lots of people to help for the fit out as we lost the origional option adn it costs us amost £300 weekly just to ave it sit there.

t has all been dreadful and i cannot warn people enough about choosing their builder and checking their insurance- if he had the right insurance this would have been covered.

had a miscarriage ays into this

e have also changed the boats name back to the very first dea - 'the Holt'

tkkun as i first said on this blog means to restore and repair the world and these are the same words being used to get out boat back to RCD compliance so we have gone off the name!

ill post when there has been some good progress as th last 12 weeks have ben so sickening that i could not imagine writing in the blog.

disaster has struck.

there were problms with the structural steel work and there has had to be 'repair and restoration' workathough on the whole everything is fine now-we are wed the money by the blder -12 thousand pounds, we do not want to go to court but will if we have to

the boat is now just about ready for lots of people to help for the fit out as we lost the origional option adn it costs us amost £300 weekly just to ave it sit there.

t has all been dreadful and i cannot warn people enough about choosing their builder and checking their insurance- if he had the right insurance this would have been covered.

had a miscarriage ays into this

e have also changed the boats name back to the very first dea - 'the Holt'

tkkun as i first said on this blog means to restore and repair the world and these are the same words being used to get out boat back to RCD compliance so we have gone off the name!

ill post when there has been some good progress as th last 12 weeks have ben so sickening that i could not imagine writing in the blog.

Sunday, July 01, 2007

final date to move to fitters

Well the boat wil be painted by the end of the first week of July now.

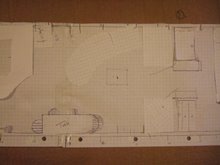

as there was more of a delay, it enabled Kevin to finish off some of the welding jobs which could have been done after the paint. we had the tow bar attached and the gas bottle storage put in the front. he gas bottles do not have to be lifted out, the come out the front of the lockers which are on each side of the front bulkhead and also make rather good seats. the front bulkhead had been finished rather quae and blnt and in the extra day we asked kev to put an overhang in and to make the sides more curves. he did this yeasterday and it looks a lot better -really has softened the front view. Andrew also aske for the prow to be changed and no there is a squarer nose. (not sure I like it so will wait till paint job blends it all in)

photos will follow and will probably be when the build is painted.

we have chosen indigo blue for the roof and front/back bulkheads and sides are to be sandstone. We will then ourselves add posibly red stripes and our boats name which wll be written out phonetically as one sees in a dictionary entry.

Adrew also managed to drill the holes for the windows and portholes so they too can get paint around them

Inside remains unvacuumed and i am not using the dyson!

all our wood and celotex has arrived and even the dog doors from the usa. We bid on a compost loo on bay and await to see if we win it in the next few days.

Our crane would cost 800 pounds and the lorry 650 bt we will share with the twoats that are already at the fitters so it will come to less. the 2 boats there do not need such a big lorry or crane so i will leave it to Anrew and roy to work out a fair split.

All we need to do now is fit windows after painted and paint inside of boat with the thermilate /paint mix and put the thinsulate strips on the roof struts.

I got a surprise ast week-and as Andrew was away, he got the surprise this week-but I will have to wait to post it on here- it means that Andrew is going to need help for the jobs that needed done as i will not be able to help wit some of them

as there was more of a delay, it enabled Kevin to finish off some of the welding jobs which could have been done after the paint. we had the tow bar attached and the gas bottle storage put in the front. he gas bottles do not have to be lifted out, the come out the front of the lockers which are on each side of the front bulkhead and also make rather good seats. the front bulkhead had been finished rather quae and blnt and in the extra day we asked kev to put an overhang in and to make the sides more curves. he did this yeasterday and it looks a lot better -really has softened the front view. Andrew also aske for the prow to be changed and no there is a squarer nose. (not sure I like it so will wait till paint job blends it all in)

photos will follow and will probably be when the build is painted.

we have chosen indigo blue for the roof and front/back bulkheads and sides are to be sandstone. We will then ourselves add posibly red stripes and our boats name which wll be written out phonetically as one sees in a dictionary entry.

Adrew also managed to drill the holes for the windows and portholes so they too can get paint around them

Inside remains unvacuumed and i am not using the dyson!

all our wood and celotex has arrived and even the dog doors from the usa. We bid on a compost loo on bay and await to see if we win it in the next few days.

Our crane would cost 800 pounds and the lorry 650 bt we will share with the twoats that are already at the fitters so it will come to less. the 2 boats there do not need such a big lorry or crane so i will leave it to Anrew and roy to work out a fair split.

All we need to do now is fit windows after painted and paint inside of boat with the thermilate /paint mix and put the thinsulate strips on the roof struts.

I got a surprise ast week-and as Andrew was away, he got the surprise this week-but I will have to wait to post it on here- it means that Andrew is going to need help for the jobs that needed done as i will not be able to help wit some of them

Thursday, June 14, 2007

update before finishing build

I have half an hour before having to go and meet Eilah's home education inspector in a local park.

Over the past 6 weeks we had a communication breakdown with the builders and some issues stored up. We have now sorted them and the build is running 16 days over schedule. Not a big issue for us really but more of an issue for ray as he wants the boat out so he can start the next one.

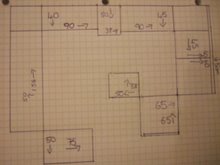

We organised a meeting and worked out that although we changed the plans on some things the extra work we created about balanced out with the things we decided not to do. This meeting also made it clearer to everyone what we wanted done before painting and in which order and what were extras. In the end the extras were about 4-5 days labour to be done after painting and as a swap we got portholes and wood for poppy and kev's own build. The extra time included making footings for the wind and solar on the roof and also building the battery box under the stairs. to save days we decided no stern rail and no hatch over the bath although we may save and do this later. we also went for opening hatches on the sides which do not cut into the roof (kidney) we can still get in them just not so easily!

It is difficult to get lorry and crane hire and co-ordniate it with another boat or two to save cost-a day of lorry is £600 & crane is £800 for a whole day so if we share with 2 others the cost is considerably less seeing as we need to go from builders to fitters to water.

The back of the boat looks fantastic but Andrew and i have some reservations about the bow and it is not the Barbara Mac thats for sure. Andrew asked for a prow to be welded on and now it looks like a real barge! the cabin sides at the front bulkhead are straight up and down and i had hoped for a curve and an overhang. ah well, i will grow a creeper up there to hide the bluntness of the sides.

Another issue that has caused us major hassle is the height inside! First Andrew measured it wrong and I spent the whole day working out how t compensate. then on remeasurement it was found that only 1.5 inches internally is missing and therefore we are not having any battening on the floor and only 25cm celotex on rof again with battening in between no more sticking up. We are insulating the metal strengthners along the roof with 3 layers of Insuladd ceramic paint and on top of that thinsulate tape (like a wet suit ).The ceramic paint is going o the inside asadouble layer which andrew and i will do when build finished and also on two of the three outside paint layers. it simply mixes i with the paint . Hopefully it will help insulate up to 15% more and keep the roof from getting too hot on the outside in summer.

the reason the cabin space got reduced is that andrew decided to make the railings be water channels which was an addition to our original plan. kev had no problem doing this but did not tell andrew that as box railings are made from the sides of the cabin metal it would reduce internal headroom- andrew did not know this - but in the end he would still have asked for these railings . it may mean he has to stoop in the back cabin only where we may need to add more ballast . it is not impossible to add more than the height of the metal on the roof and floor so the boards are also going straight into the metal. we were going to go for marine ply then when we could afford it add boards on top but now for height reasons it has to be just boards as who wants to spend £800 on marine ply floor and rip it up to put in floorboards later?

The solar panel fittings are straight forward and the windmill just needs a pole mount and we got a winch so it will be on a 4m pole which will come down over the roof when we move. we decided to make out chimney extra high too and it too will be manually taken down when on the move and all summer!

we also decided finally on colour- dark indigo on roof and bulkheads and a sandstone on the rest. We will paint coachlines ourselves later. We think we would like this to look matt rather than gloss.

My daughter is being looked after for a week after the paint is done so andrew and I will zinc oxide the inside with insuladd added to the paint and put in the thinsulate tape .Then put in the windows!

Over the past 6 weeks we had a communication breakdown with the builders and some issues stored up. We have now sorted them and the build is running 16 days over schedule. Not a big issue for us really but more of an issue for ray as he wants the boat out so he can start the next one.

We organised a meeting and worked out that although we changed the plans on some things the extra work we created about balanced out with the things we decided not to do. This meeting also made it clearer to everyone what we wanted done before painting and in which order and what were extras. In the end the extras were about 4-5 days labour to be done after painting and as a swap we got portholes and wood for poppy and kev's own build. The extra time included making footings for the wind and solar on the roof and also building the battery box under the stairs. to save days we decided no stern rail and no hatch over the bath although we may save and do this later. we also went for opening hatches on the sides which do not cut into the roof (kidney) we can still get in them just not so easily!

It is difficult to get lorry and crane hire and co-ordniate it with another boat or two to save cost-a day of lorry is £600 & crane is £800 for a whole day so if we share with 2 others the cost is considerably less seeing as we need to go from builders to fitters to water.

The back of the boat looks fantastic but Andrew and i have some reservations about the bow and it is not the Barbara Mac thats for sure. Andrew asked for a prow to be welded on and now it looks like a real barge! the cabin sides at the front bulkhead are straight up and down and i had hoped for a curve and an overhang. ah well, i will grow a creeper up there to hide the bluntness of the sides.

Another issue that has caused us major hassle is the height inside! First Andrew measured it wrong and I spent the whole day working out how t compensate. then on remeasurement it was found that only 1.5 inches internally is missing and therefore we are not having any battening on the floor and only 25cm celotex on rof again with battening in between no more sticking up. We are insulating the metal strengthners along the roof with 3 layers of Insuladd ceramic paint and on top of that thinsulate tape (like a wet suit ).The ceramic paint is going o the inside asadouble layer which andrew and i will do when build finished and also on two of the three outside paint layers. it simply mixes i with the paint . Hopefully it will help insulate up to 15% more and keep the roof from getting too hot on the outside in summer.

the reason the cabin space got reduced is that andrew decided to make the railings be water channels which was an addition to our original plan. kev had no problem doing this but did not tell andrew that as box railings are made from the sides of the cabin metal it would reduce internal headroom- andrew did not know this - but in the end he would still have asked for these railings . it may mean he has to stoop in the back cabin only where we may need to add more ballast . it is not impossible to add more than the height of the metal on the roof and floor so the boards are also going straight into the metal. we were going to go for marine ply then when we could afford it add boards on top but now for height reasons it has to be just boards as who wants to spend £800 on marine ply floor and rip it up to put in floorboards later?

The solar panel fittings are straight forward and the windmill just needs a pole mount and we got a winch so it will be on a 4m pole which will come down over the roof when we move. we decided to make out chimney extra high too and it too will be manually taken down when on the move and all summer!

we also decided finally on colour- dark indigo on roof and bulkheads and a sandstone on the rest. We will paint coachlines ourselves later. We think we would like this to look matt rather than gloss.

My daughter is being looked after for a week after the paint is done so andrew and I will zinc oxide the inside with insuladd added to the paint and put in the thinsulate tape .Then put in the windows!

Tuesday, June 12, 2007

a new name

A lot has happened in the last 4 weeks. A glitch which stooped communication for a couple of weeks , a sorting out, the windows cut , paint colours chosen and a finalised version of what we feel we want help with when the boat is moved to the fitters.We have also now chosen another new name for the boat!!

We are calling her TIKKUN.

It is Hebrew and it means to repair and restore the world and that comes form the magazine of the liberal- progressive movement but is a tenant of Judaism.

We think she will now be finished 3 weeks later than first thought- middle of June.It is now the Tuesday 12th June and it may be ready to paint next Monday. It has been hectic and I will post again at another date the cruscial last few weeks of the build.

We are calling her TIKKUN.

It is Hebrew and it means to repair and restore the world and that comes form the magazine of the liberal- progressive movement but is a tenant of Judaism.

We think she will now be finished 3 weeks later than first thought- middle of June.It is now the Tuesday 12th June and it may be ready to paint next Monday. It has been hectic and I will post again at another date the cruscial last few weeks of the build.

Monday, May 07, 2007

getting more bits!

We had decided on a plastic agricultural water storage tower cut off to become a bath. we were going to clad it in wood and have Kev cut a roof slide so we could see the stars but once I saw this item on ebay, the plastic tub went out the window. this had to be my best bargain at £90 + £55 to deliver door to door! we are also not having the roof hatch as time doe snot permit-more on this later

We tested out the spiral staircase and it works well. Andrew and Ian have designed all the battery boxes to go undeer the stairs and each stair moves out the way (which also means we have no bannister....hmmmm?)

i also bid on a solid oak floor on ebay but chickened out at £500 because i knew we had to lift it ourselves but could not find out if it was glued down or not which would have been a horrible job with much wastage due to breaking some planks. Instead i am trying the wood recycling centers -they are found in every major city but Andrew picked up a hitch hiker called Matt tatt (who knows Steve and probably Joe- or welder Joe as everyone calls him) and he said the London centre had everything we needed! will try soon. stop press- got recycled planed pine boards for really cheap on ebay - £6 sq M and although they are not the wide boards i had hoped for they are better than marine ply and came in at £300 the whole floor.

micky, mike wood oes by all names) has finished stripping our chairs and tabel. the oak table was free- the gardeners of the estate i live on gave it to me and it was large and stained an ugly dark brown. Now it is 2ft wide and a lovely light oak!! he is also making balance boards for andrew's practice and possibly going to make porthole liners. stop press he is now also doing the kitchen.

andrew wants to save renovating the porthholes for a later date as he thinks it looks more authentic as they are

but I think the scratches and staining on the glass may drive me mad every time i look at the view.

We tested out the spiral staircase and it works well. Andrew and Ian have designed all the battery boxes to go undeer the stairs and each stair moves out the way (which also means we have no bannister....hmmmm?)

i also bid on a solid oak floor on ebay but chickened out at £500 because i knew we had to lift it ourselves but could not find out if it was glued down or not which would have been a horrible job with much wastage due to breaking some planks. Instead i am trying the wood recycling centers -they are found in every major city but Andrew picked up a hitch hiker called Matt tatt (who knows Steve and probably Joe- or welder Joe as everyone calls him) and he said the London centre had everything we needed! will try soon. stop press- got recycled planed pine boards for really cheap on ebay - £6 sq M and although they are not the wide boards i had hoped for they are better than marine ply and came in at £300 the whole floor.

micky, mike wood oes by all names) has finished stripping our chairs and tabel. the oak table was free- the gardeners of the estate i live on gave it to me and it was large and stained an ugly dark brown. Now it is 2ft wide and a lovely light oak!! he is also making balance boards for andrew's practice and possibly going to make porthole liners. stop press he is now also doing the kitchen.

andrew wants to save renovating the porthholes for a later date as he thinks it looks more authentic as they are

but I think the scratches and staining on the glass may drive me mad every time i look at the view.

Tuesday, April 24, 2007

she is very big

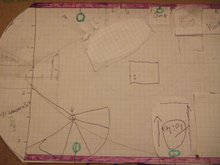

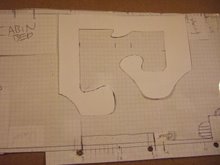

well our sides are up but not yet finished and we managed to get an idea of what the spiral staircase may look like inside and also the bath.

mapped out the measurements again and we have got it correct except the bedroom for the kids will take up 9.5 feet not 10.

mapped out the measurements again and we have got it correct except the bedroom for the kids will take up 9.5 feet not 10.

Subscribe to:

Comments (Atom)